Rock Reamer & Hole Opener

HDD Rock Reamer & Hole Opener

Rock Reamer & Hole Opener is a commonly used reamer in Horizontal Directional Drilling(HDD) construction. This type of reamer has high reaming efficiency, simple structure, convenient operation, and strong applicability. The Rock Reamer & Hole Opener use the cone drill bit for hole open, which has high drilling efficiency and rock breaking ability, and can quickly complete the hole expansion operation. The key components of the Rock Reamer & Hole Opener are made of high-quality materials, ensuring its reliability and service life. Meanwhile, reasonable structural design also reduces the occurrence of faults. The Rock Reamer & Hole Opener can adapt to the drilling needs of different strata, such as soft soil layers, sand layers, gravel layers, etc. At the same time, its efficient rock breaking ability can also overcome the problem of drilling in hard rock formations. The design of the tooth wheel reamer fully considers operational safety and adopts various safety measures, such as explosion-proof devices, safety valves, etc., to ensure the safety of operators.

Rock Reamer & Hole Opener with Milling tooth

Rock Reamer & Hole Opener with Milling tooth has relatively poor wear resistance. In order to improve its wear resistance, a hard alloy layer is often welded on top of it.

Rock Reamer & Hole Opener with Inlaid tooth

Rock Reamer & Hole Opener with Inlaid tooth is made of hard alloy. These types of teeth have high hardness, good wear resistance, and long service life. The disadvantage is that the inlaid teeth are brittle, prone to collapse.

- Rock Reamer & Hole Opener with Milling tooth

Rock Reamer & Hole Opener with Milling tooth has relatively poor wear resistance. In order to improve its wear resistance, a hard alloy layer is often welded on top of it. - Rock Reamer & Hole Opener with Inlaid tooth

Rock Reamer & Hole Opener with Inlaid tooth is made of hard alloy. These types of teeth have high hardness, good wear resistance, and long service life. The disadvantage is that the inlaid teeth are brittle, prone to collapse.

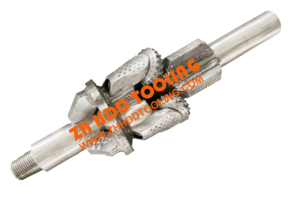

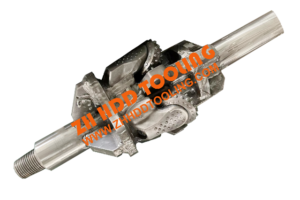

Structure Of HDD Rock Reamer & Hole Opener

The Rock Reamer & Hole Opener consists of a rear stabilizer plate, a rear baffle plate, a core shaft, a front baffle plate, a front stabilizer ring, a front stabilizer plate, a tooth wheel, a tooth palm, etc.

Features & Benefits of ZH Tooling Rock Reamer & Hole Opener

- ZH Tooling Rock Reamer & Hole Opener has a wide range of applications and can be applied to various formations with different hardness.

- In order to meet the construction requirements of Horizontal Directional Drilling(HDD) different working conditions , ZH Tooling Rock Reamer & Hole Opener can accept customization, according to customer requirements

- The hydraulic cutting speed is fast, and the Rock Reamer & Hole Opener is smooth in sand removal, which effectively reduces the accumulation of rock and sand.

- The roller body of the ZH Tooling Rock Reamer & Hole Opener is made of hot applied wear-resistant alloy, which is more wear-resistant, greatly improving the service life of the reamer, providing construction efficiency, and reducing Horizontal Directional Drilling(HDD) costs.

- ZH Tooling Rock Reamer & Hole Opener has professional design for anti loosening teeth to prevent damage to the teeth bearings during Horizontal Directional Drilling(HDD) construction and prevent them from falling off inside the drill hole, resulting in construction accidents.

- The high-quality welding process provides a reliable guarantee for improving the overall quality of the Reamer & Hole Opener. Overheating during welding working process can damage the tooth seal and bearings, thereby reducing the service life of the Reamer & Hole Opener.

- The roller of ZH Tooling Rock Reamer & Hole Opener adopts a special design, which allows the Rock Reamer & Hole Opener to achieve a better straightening effect during operation, improves the slag removal effect of the Rock Reamer & Hole Opener, reduces repeated rock breaking wear of the tooth wheel, and improves the speed of Horizontal Directional Drilling(HDD) work.

- High strength, good wear resistance, long service life, and good safety performance.